Design skills

Get quick advice on creating magnesium alloy, aluminum alloy, and stainless steel parts for CNC machining and die casting. Designs that consider manufacturability can shorten production time and reduce production costs.

CNC|Errors to avoid during die casting

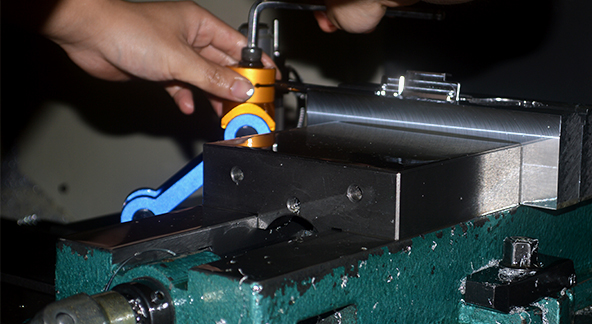

Die casting machining

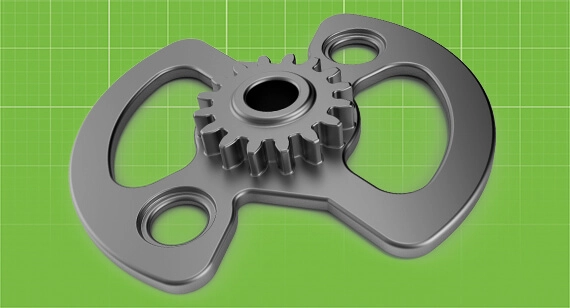

CNC machining design considerations

When developing parts for CNC machining, fixtures on the surface of the part are essential to improve the moldability of the part. Without it, the parts may have the risk of undesirable surface defects, and may be bent, broken or warped due to the forming stress caused by metal deformability

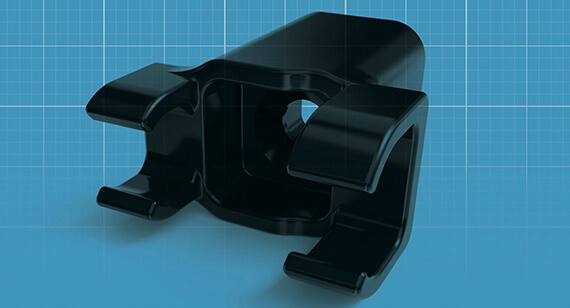

Die casting design flaw blues

Early detection of potential appearance defects, such as sinking, braided lines, burrs, blush and other problems during the design process of die-casting processing, can not only improve the appearance of the part, but also improve the overall formability

Design Points

We have compiled the most important manufacturing techniques into three downloadable design guides about 3D printing, machining and molding. Everyone is committed to improving manufacturability and reducing production costs through design, material selection, etc.