Surface-chemical treatment

Surface treatment-chemical solution is an industrial surface treatment process that can be used to create conceptual models, product prototypes and complex parts with complex geometries within one day. Chemical surface treatment can provide a variety of materials, extremely high feature resolution and high-quality surface finish.

How does chemical surface treatment work?

Chemical surface treatment is the use of chemical knowledge to react on the surface of magnesium alloy products, so that a high-quality coating is formed on the surface of the parts of the product, so that it is not easy to be oxidized and protects the appearance of the parts.

Newly built parts are taken out of the machine and entered into the laboratory, where a solvent is used to remove any other resin. After the parts are completely cleaned, the support structure can be removed manually. From there, the part undergoes a UV curing cycle to completely cure the outer surface of the part. The final step in the SLA process is to apply any custom or customer-specified finishing. When using SLA built-in parts, the exposure of ultraviolet rays and moisture should be minimized to avoid degradation.

- Fastest delivery within 1 day

- Real-time quotation of surface treatment magnesium alloy parts

- High precision, function as low as 0.002 cm.

- Good surface quality of surface prototypes

- Magnesium alloy passivation

- Oxide black

- Powder spraying, painting, sandblasting

Magnesium alloy micro-arc oxidation

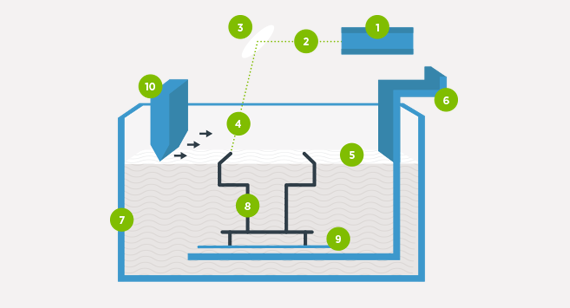

The micro-arc oxidation of magnesium alloy refers to the electrochemical reaction of magnesium alloy parts after a period of treatment in the case of low temperature solution under the action of the anode and the applied voltage, and then the use of magnesium alloy parts and the treatment overnight. A surface treatment technology that generates an oxide film layer on the surface of CNC machined parts to protect magnesium alloy products

Anodizing treatment method

In order to enrich the color of the product, we can usually perform some oxidation treatment. Oxidation treatment can make all colors except white.

Chemical treatment design guidelines

Data resources

Current Status of Magnesium Aluminum Alloy Surface Treatment Technology

Corrosion resistance of magnesium and magnesium alloys in the atmosphere

Standard for magnesium alloy sacrificial anodic oxidation products

Magnesium alloy notebook shell sandblasting and painting