Chemical treatment: Guidelines for chemical surface treatment

Our basic guidelines for chemical surface treatment include important design considerations, magnesium alloy passivation, black oxide, painting, powder spraying, sandblasting , To help the protection of product parts, improve appearance and reduce overall production time.

Size

Maximum size

| Normal resolution | 80cm x 60cm x 30cm |

|---|

| Normal resolution | 800mm x 600mm x 300mm |

|---|

Accuracy

Layer thickness

| Normal resolution | 0.002~0.01 cm |

|---|---|

| High resolution | 0.002~0.005 cm |

| Micro resolution | 0.001~0.002 cm |

| Normal resolution | 0.02~0.1 mm |

|---|---|

| High resolution | 0.02~0.05 mm |

| Micro resolution | 0.01~0.02 mm |

Minimum feature size

| Normal resolution | XY drawing plane is 0.0254cm (Z generating direction is 0.0406cm) |

|---|---|

| High resolution | XY drawing plane is 0.01016cm (Z generating direction is 0.0406cm) |

| Micro resolution | XY drawing plane is 0.00508cm (Z generating direction is 0.0203cm) |

| Normal resolution | XY drawing plane is 0.254mm (Z generating direction is 0.406mm) |

|---|---|

| High resolution | XY drawing plane is 0.1016mm (Z generating direction is 0.406mm) |

| Micro resolution | XY drawing plane is 0.0508mm (Z generating direction is 0.203mm) |

For a well-designed part, the X/Y dimension tolerance of the first centimeter is ±0.05mm, plus ±0.001mm/mm, and the Z dimension tolerance of the first centimeter is ±0.005mm, plus ± 0.001mm/mm. It can usually reach (0.001mm/mm). Please note that tolerances may vary based on the geometry of the part.

Materials

Magnesium alloy

- Magnesium alloy AZ91D

- Magnesium alloy ZK61

- Magnesium alloy AZ31

- Magnesium alloy AZ61

- Magnesium alloy AM60

Aluminum alloy

Stainless steel

Surface treatment

| Incomplete | From the remnants of the support structure, dots or upright "pen nibs" can still be seen on the bottom of the part. |

|---|---|

| Natural |

Sand the support surface to eliminate the support tip. |

| Standard | The surface of the support has been polished, and the entire part has been finely sandblasted to maintain a consistent appearance. Note that these layers still exist. |

| Customization |

Can provide soft paint, transparent part surface treatment, spray painting, masking, color matching, decal/graphic and texture surface treatment. |

Special Operations

Painting

We use coating technology to spray paint, dust, and sand the surface of the product, so that the parts have the appearance, feel and strength of metal, but no weight. The strength, stiffness and heat resistance of the material are combined with nickel plating to make the strength, stiffness, impact resistance and heat resistance reach the level that military parts could not reach before.

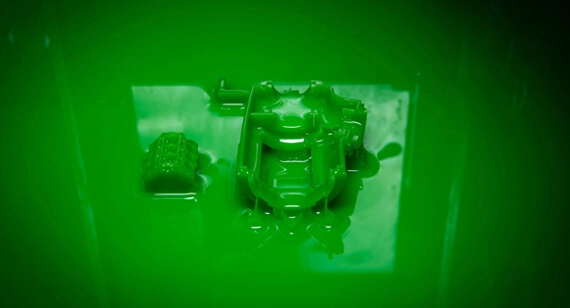

Microfluidics

Our microfluidic manufacturing process is an improved form of high-resolution product surface treatment, which uses high-end chemical element coatings. The parts are waterproof and moisture-proof, so they can be used well in the lens and flow visualization model.

Customized organization

Customized processing is a combination of science, technology and art, which can transform parts into your exact specifications. Completion includes:

- Soft touch paint

- Clear parts finishing

- Paint finish

- Masking

- Color matching

- Textures/graphics

- Texture

Equipment

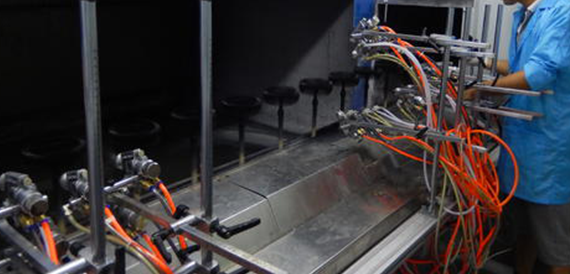

Our surface treatment is composed of chemical surface treatment, electric surface treatment, and mechanical surface treatment. In high-resolution mode, chemical processing can give parts with minimal functionality and clear details, while in normal-resolution mode, they can make cost-effective parts very quickly.

The chemical surface treatment has a huge build volume of 800 mm x 600 mm x 300 mm, but it can still easily image very fine parts.