Adhering to the quality of military products

For the time being, only self-processed products are accepted for quality inspection

Certificate of Certification

ISO 9001:2015 | Military Quality Certification

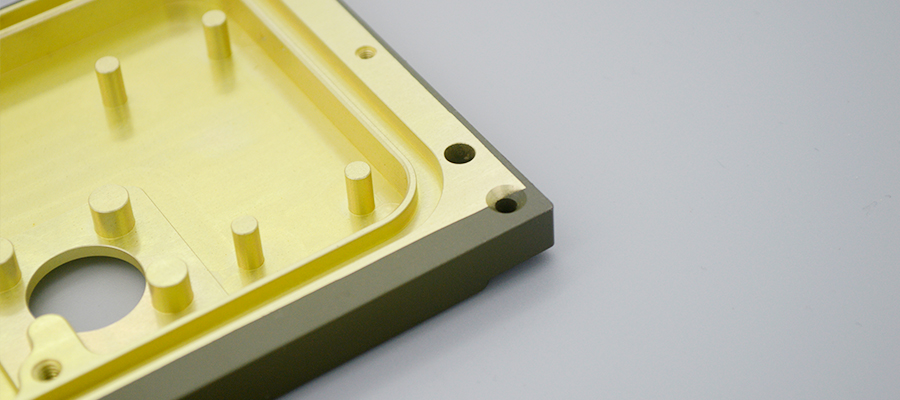

Are you ready to manufacture parts in a more cost- and time-saving way? Our high-quality magnesium alloy, aluminum alloy, and stainless steel materials can help you reduce quality risks and limit overall production costs at every step of the entire product cycle.

Are you ready to manufacture parts in a more cost- and time-saving way? Our high-quality magnesium alloy, aluminum alloy, and stainless steel materials can help you reduce quality risks and limit overall production costs at every step of the entire product cycle.

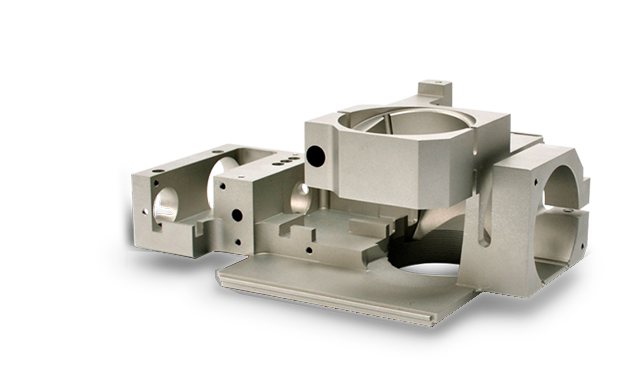

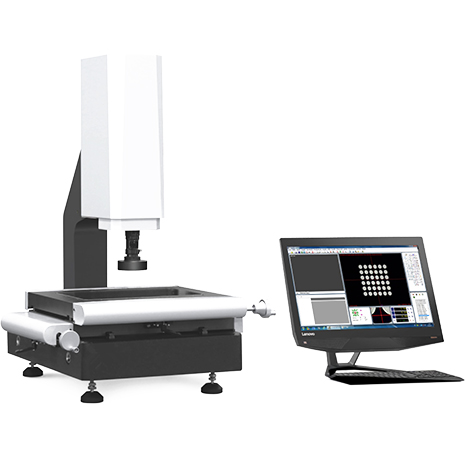

Quality inspection

Accuracy detection

Accuracy inspection is the accuracy inspection of magnesium alloy, aluminum alloy, stainless steel products using precision detectors, three-dimensional, two-dimensional, micrometer, caliper, and altimeter

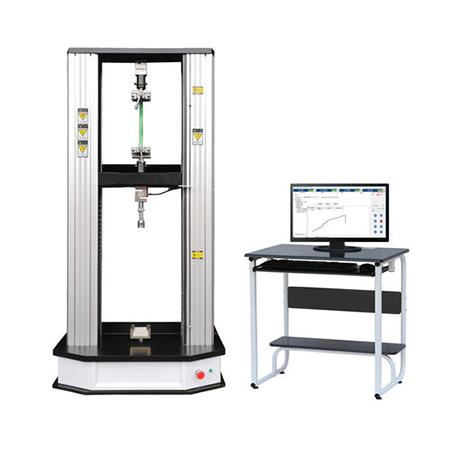

Hardness test

Tensile testing of magnesium alloy, aluminum alloy, stainless steel, and falling ball testing of finished samples

Performance testing

Performance testing is the process of testing the properties of raw materials and the adhesion, as well as the process of thermal shock and salt spray testing

Inspection on demand

High quality requirements, achievement of military quality

"The Green Bat Technology has brought us a lot of inspiration. We can extract parts from actual materials at a very fast speed for use in final production."

Additional links and resources

Record number: Guangdong ICP No. 14004399 @cyanbat