We are not only the fastest manufacturing supplier for processing prototypes, but also the most reliable source for on-demand production of parts. Why is this important? You have a single source supplier from proof of concept to short-term production.

In addition to stricter tolerances, hardware assembly, first article inspection (FAI) reports, material certification, and other finishing such as anodizing and chromate plating In addition to options, we also provide more competitive high-volume pricing.

It is CNC machining designed according to the needs of the project (whether it is prototype or production).

![]()

price breakthrough

Start from the number of parts 15

![]()

delivery time

The fastest delivery is 5 days

![]()

Surface treatment

Anodic oxidation and chromate plating

![]()

quantity

15 to 1,000 or more parts

4 reasons to choose a prototype laboratory for machined production parts

1. Reduce the price of parts when the batch is large

When ordering larger quantities of production parts, parts costs can be reduced.

2. Inspection report and certification

Get additional quality assurance from regular FAI reports, CoC documents and ISO9100 certification.

3. More organization options

Select complete parts from anodizing and chromate plating from a supplier.

4. Supply chain flexibility

Avoid storage fees by ordering only the quantity you need per month (starting with quantity 15).

After processing

Standard parts

Sandblasting beads (surface)

Tolerance range

- Workshop tolerance = +/- 0.005

- Capable of accommodating +/-0.002 reaming holes (requires printing

- At most +/- 0.002 feature position on the same side (need to print

Surface roughness

- Straight surface = 63 µ in

- Surface = 125 µ in

Surface treatment options

A variety of surface finishes can be used to produce processed parts.

Quality Quality

Check whether the appearance of all parts meets the process standards, and check whether the dimensions on at least three dimensions (usually X, Y and Z) are qualified, but for processed parts, we also provide regular inspection reports.

Anodizing

This process is usually used for machined aluminum parts. Anodizing options of Greenbat Technology:

- Second category

- Comply with ROHS

- Level 1 (clear)

- Level 2 (black)

Chromate plating

Chromate plating options of Greenbat Technology:

- Type I, non-ROHS (yellow)

- Type II, ROHS (clear)

- Level 1A: Maximum protection of painted or unpainted corrosion

- Level 3: Provide maximum corrosion protection when low resistance is required

Hardware assembly

- Pin

- PEM plugin

- Spiral oil

- Key insertion

CNC automation design

Our new guide helps you prepare CAD models to ensure they are easy to use in our end-to-end digital manufacturing process. According to our guidelines, parts can even be machined with high precision.

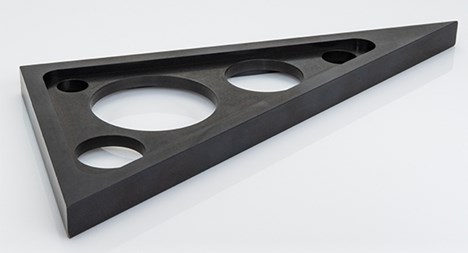

CNC processed production materials

| Materials | Maximum part size |

|---|---|

| Magnesium alloy AZ91D | 800mm x 600mm x 300mm |

| Magnesium alloy ZK61 | 800mm x 600mm x 300mm |

| Magnesium alloy AZ31 | 800mm x 600mm x 300mm |

| Magnesium alloy AZ61 | 800mm x 600mm x 300mm |

| Magnesium alloy AM60 | 800mm x 600mm x 300mm |

Quality report

When all your parts are processed on Green Bat Technology, you can rest assured that these parts will be produced in ISO and ITAR-certified factories and will never be outsourced to another machinery factory. Check whether the appearance of all parts meets the process standards, and check whether the dimensions on at least three dimensions (usually X, Y and Z) are qualified, But for processed parts, we also provide regular inspection reports, such as FAI, CofC documents, and other certifications, such as ISO 9001 and ISO2015.