Mg alloy CNC milling service

Prototypes and production parts can be processed as fast as 1 day

certification certificate

ISO 9001:2015 | AS9100D | Military certification

CNC milling

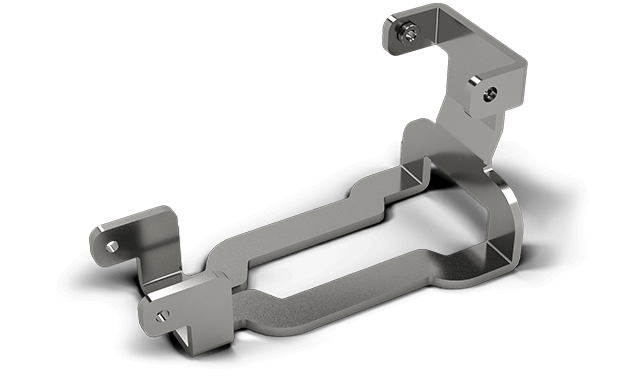

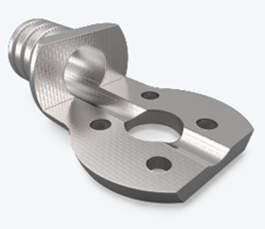

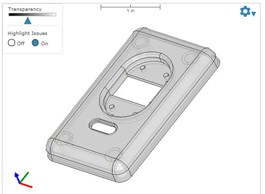

Our CNC milling process can produce customized prototypes and final-use production parts within 1 day. We use 3-axis milling to 5-axis indexing milling technology to manufacture parts with more than 30 engineering grade magnesium alloy materials, aluminum alloys, and stainless steel. Using machined production parts, in addition to first article inspection (FAI) reports, material certification, and other finishing options such as magnesium alloy passivation, micro-arc oxidation, electroplating, anodizing, etc., you can also get more Competitive price.

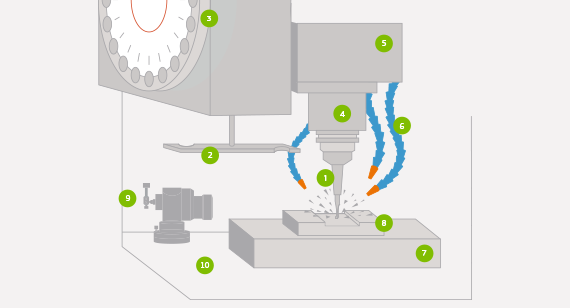

How does CNC milling work?

CNC milling is a subtractive manufacturing process. First, a small piece of magnesium alloy or aluminum alloy, stainless steel material is fixed in the CNC rolling mill. Use G code to program CNC machine tools to quickly mill parts from the raw material block. Our 3-axis to 5-axis CNC machine tools are equipped with various tool sets to maximize efficiency and production speed.

The processed magnesium alloy parts remain intact, which usually means that they show visible tool marks. Some metal parts can provide more surface treatment options, such as passivation, micro-arc oxidation, electroplating, and anodizing. After completing the run and applying the required surface treatments, the parts are boxed and shipped shortly thereafter. .

- The fastest delivery is 1 day

- Parts start at ¥65

- Function prototype

- Jigs and fixtures

- Small production components

About Us Greenbat Technology

Quickly browse our 980 square meter CNC machining factory in Shenzhen to learn how we can quickly manufacture parts within 24 hours.

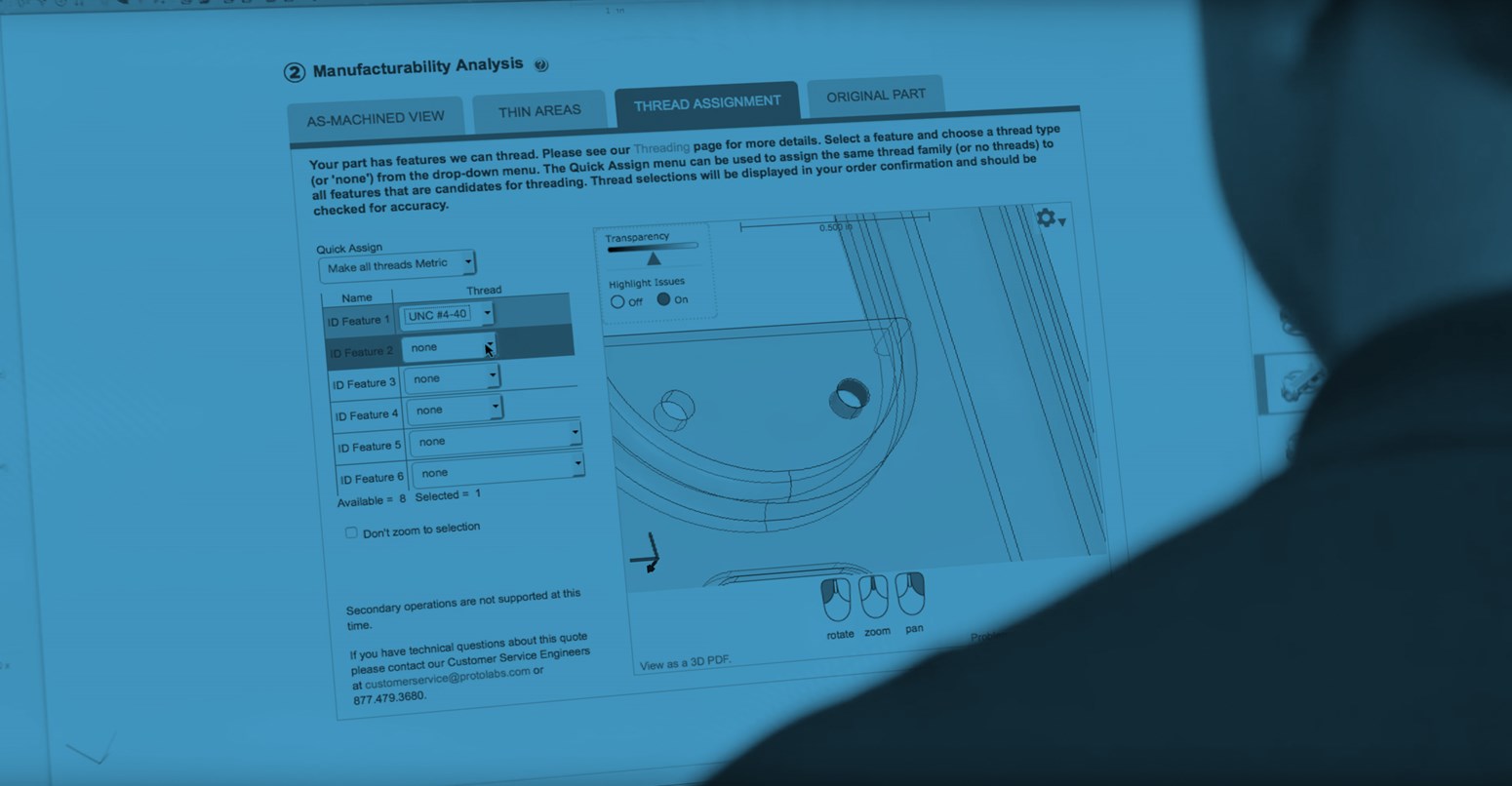

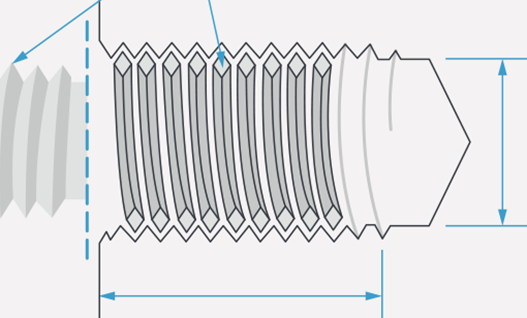

Threaded holes on machining parts

Our CNC machining services can easily add thread features to milled and turned parts. See which thread options are available.

Design Guidelines

Milling material

Data resources

Military industry precision CNC magnesium alloy workpiece housing

Rapid prototyping of magnesium alloy aviation parts

Processing of parts for medical physiotherapy equipment

Computer reinforcement parts kit