The country’s leading medical equipment development companies have turned to Greenbat Technology to unleash the advantages of digital manufacturing models. From connected devices to large-scale personalization of healthcare products, digital manufacturing accelerates development and market introduction through rapid prototyping, bridging tools, and small batch production.

Why do medical device development companies use Green Bat technology?

Interactive design analysis

Important design adjustments are made through the manufacturability (DFM) feedback of each quotation to save development time and cost.

Small batch production

Before and after the product is put on the market, you can get low-volume production parts as soon as one day to simplify your supply chain.

Bridge tools before production

Use affordable bridge tools for design and market validation before capital investment in tools.

![]()

Medical materials

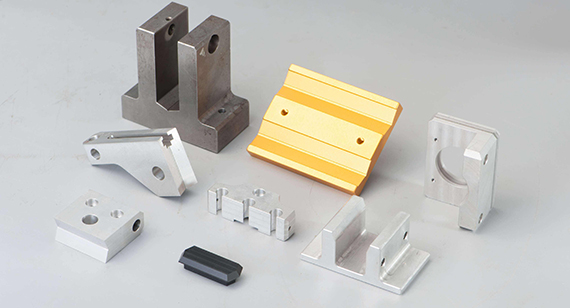

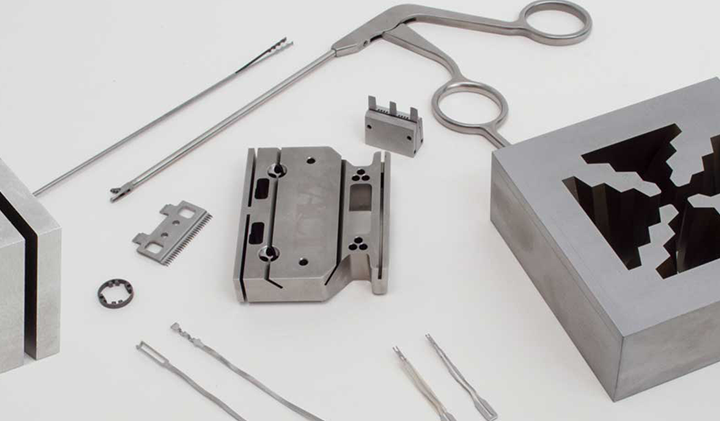

Choose from aluminum alloy to medical grade magnesium alloy, surface treatment micro-resolution and micro-fluid parts, and hundreds of other metal materials.

Rapid prototyping

Create CNC die-casting processing in production-grade materials for functional and regulatory testing, or surface treatment and quality testing before medical procedures.

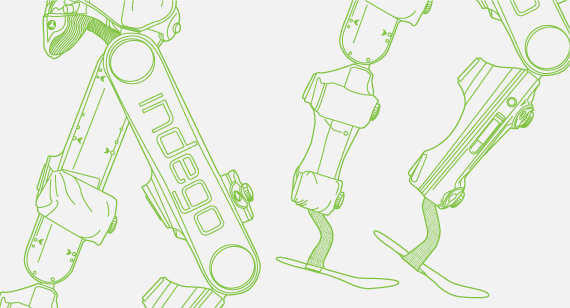

Shenzhen medical equipment brings robot exoskeleton to life through the digital manufacturing of Greenbat Technology |

|

Engineers of medical equipment in charge of motion and control technology need to speed up development and reduce the design risk of their robot exoskeleton. The combination of digital manufacturing technology and automatic quotation enables a highly iterative design process without wasting time to market. |

| Read successfully Case |

Which material is best for medical applications?

Magnesium alloy:. Fast heat dissipation, light weight, good rigidity, certain corrosion resistance and dimensional stability, impact resistance, wear resistance, good attenuation performance and easy recycling; in addition, High thermal and electrical conductivity, non-magnetic, good shielding and non-toxic characteristics. .

Aluminum alloy:. It has the characteristics of low density, good mechanical properties, good processing properties, non-toxic, easy to recycle, electrical conductivity, heat transfer and corrosion resistance.

Stainless steel. Beautiful surface and diversified use possibilities; Good corrosion resistance, longer durability than ordinary steel; Good corrosion resistance; High strength, so the possibility of using thin plates is great; High temperature resistance High oxidation and strength, so it can resist fire.

Micro-resolution:. Magnesium alloy is a proprietary material developed by Greenbat Technology and Research Institute, which is used to construct complex product parts with a size as small as 0.025mm. .

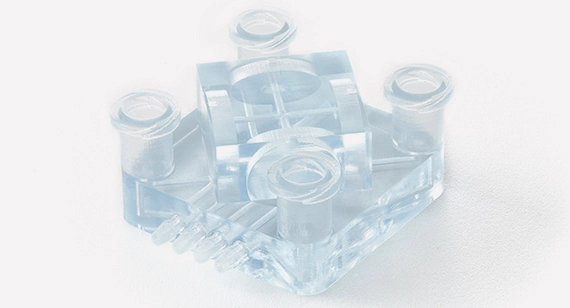

Microfluidics: Watershed (similar to ABS) and Accura 60 (similar to PC) are transparent materials that can be used for microfluidic parts and transparent parts such as lenses and housings.

Medical alloys: There are more than 20 metal materials to choose from between machined metal and die-cast metal and sheet metal, which can be used for medical parts, instrumentation and other applications. Metals such as titanium and inconel have temperature resistance, while various stainless steel materials have corrosion resistance and strength.

| Common medical applications |

|---|

|

Between machined metal and die-cast metal and sheet metal, there are more than 20 metal materials to choose from, which can be used for medical parts, instrumentation and other applications. Metals such as titanium and inconel have temperature resistance, while various stainless steel materials have corrosion resistance and strength.

|

"Now, it has been integrated into our design and R&D process...For me (ordered from Greenbat Technology) molds for medical equipment parts are much easier than paying a mortgage online."