Mg alloy CNC turning service

Prototypes and production parts can be processed as fast as 1 day

certification certificate

ISO 9001:2015 | AS9100D |Military certification

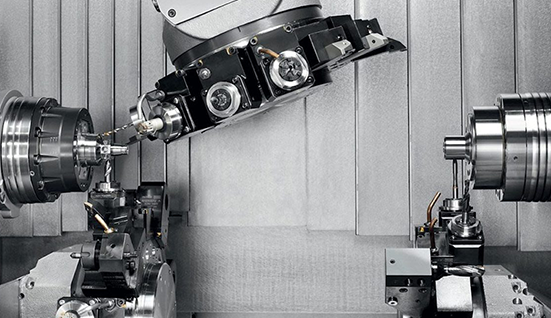

CNC turning

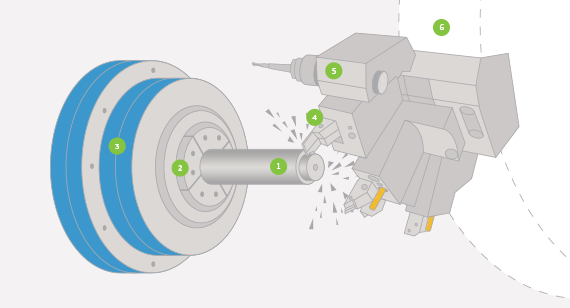

Our CNC turning process can produce customized prototypes and final-use production parts within 1 day. We use CNC lathes with movable tools, so we can machine axial and radial holes, planes, grooves and grooves.

What is CNC turning?

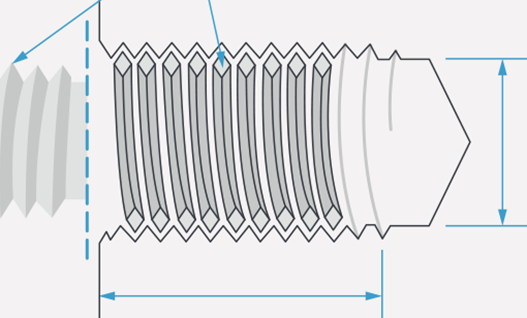

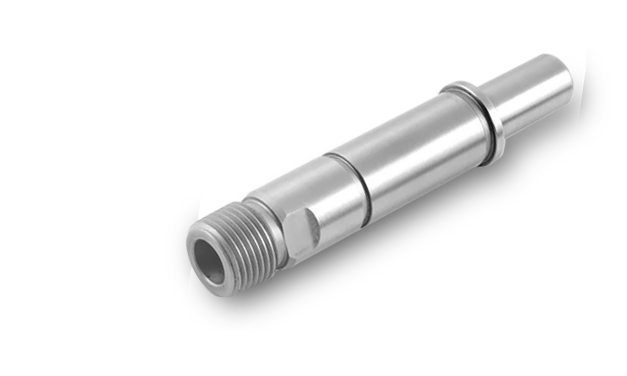

CNC turning is a subtractive manufacturing process in which a metal rod is rotated while pressing the cutting tool on the blank to remove material and produce the final part. Our CNC lathes are also equipped with live tools, which can process plane features and holes on the workpiece. External diameter (OD) and internal diameter (ID) threads are also available.

The turned parts can then be left for machining, with visible tool marks or sandblasted. After the operation is completed, the parts will be inspected, packaged and shipped soon.

- The fastest delivery is 1 day

- Parts start at ¥65

- Functional prototypes and end-use parts

- Parts with cylindrical features

- Parts with axial and radial holes, flats, grooves and slots

Why choose the CNC turning processing of the green bat

Accelerate product development, reduce costs and optimize your supply chain

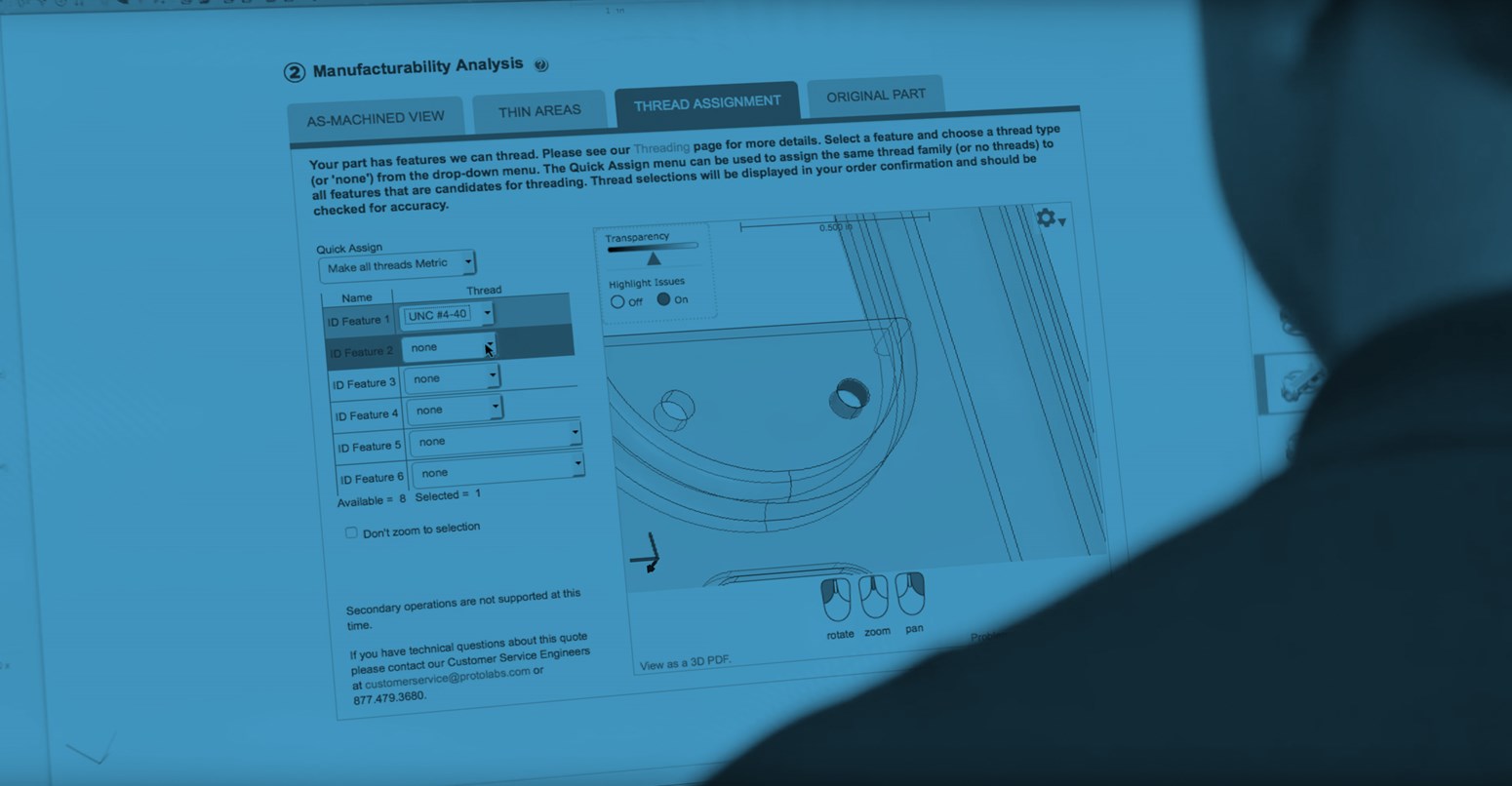

Machining threaded holes on magnesium alloy parts

Our CNC machining services can easily add thread features to milled and turned parts. See which thread options are available.

Design Guidelines

Turning materials

Data resources

Common sense of precision CNC machining

What are precision machining lathe parts

Difficulties in stainless steel processing

How to reduce the cost of CNC machining

Interactive design analysis for free within a few hours

Contact usRecord number: Guangdong ICP No. 14004399 @cyanbat