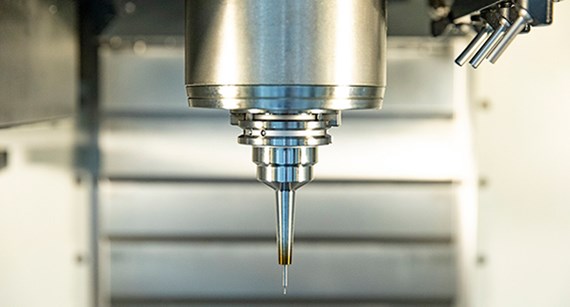

You know that we are the fastest manufacturer of mechanical parts, but sometimes your project needs exceed the need for speed. We machine high-precision parts with a variety of finishing and reporting options-exactly what you need with high-end specifications.

When you need a small number of parts but a large number of parts, precision machining makes sense. Delivery time can still be as short as 10 days!

The advantages of precision machining

Processing complexity usually brings high-level requirements. To ensure that your parts meet your needs, we provide design feedback from application engineers. You will also get:

- The tolerance is as small as +/- 0.005mm

- Meet quality requirements (including CoC, FAI, ISO 9001 and ISO2015)

- Fully machined features (no material left)

Precision Machining Design Guidelines

Maximum size

| Three-axis milling | 110cm. x 80 cm. x 50cm. |

|---|---|

| Four-axis milling | 50 cm. x 35 cm. x 20cm. |

| Five-axis milling | 50 cm. x 35 cm. x 20cm. |

| Electric discharge machining | 60cm. x 50cm. x 30cm. |

| CNC cutting | 10 cm. x 18 cm. |

| Three-axis milling | 1100mm x 800mm x 650mm |

|---|---|

| Four-axis milling | 500mm x 350mm x 200mm |

| Five-axis milling | 500mm x 350mm x 200mm |

| Electric discharge machining | 600mm x 500mm x 300mm |

| CNC cutting | 100mm x 180mm |

< /p>

< /p>

Other design considerations

- Maximum part weight: 34.02kg

- 3D CAD files are preferred; other specifications are accepted

Minimum size

| Three-axis milling | < 0.10 cm. x <0.20 cm. x 0.20 cm. |

|---|---|

| Four-axis milling | < 0.10 cm. x <0.20 cm. x 0.20 cm. |

| Five-axis milling |

< 0.10 cm. x <0.20 cm. x 0.20 cm. |

| Electric discharge machining |

< 0.10 cm. x <0.20 cm. x 0.20 cm. |

| CNC cutting |

0.093 cm. diameter |

**Minimum material thickness of magnesium alloy and aluminum alloy, steel: 0.125mm

| Three-axis milling | 2.54mm x 5.08mm x 5.08mm* |

|---|---|

| Four-axis milling | 2.54mm x 5.08mm x 5.08mm* |

| Five-axis milling |

2.54mm x 5.08mm x 5mm* |

| Electric discharge machining |

2.54mm x 5.08mm x 5mm* |

| CNC cutting |

0.093 cm diameter |

*Minimum material thickness of magnesium alloy and aluminum alloy, stainless steel: 0.125mm

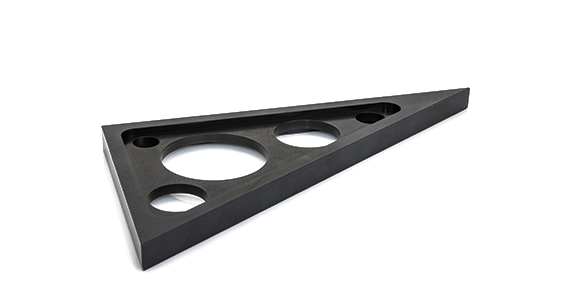

CNC automation design

Our new guide helps you prepare CAD models to ensure they are easy and comfortable in our end-to-end digital manufacturing process. According to our guidelines, parts can even be machined with high precision.

Materials

Magnesium alloy products

- AZ91D

- ZK61

- AZ31

- AZ61

- AM60

- Customer grade

Other materials

- Aluminum alloy

- Stainless steel

- Customer provides materials

Organization and post-processing

- Magnesium alloy passivation

- Micro-arc oxidation of magnesium alloy

- Electrophoresis

- Powder spraying

- Plating

- Spray paint

- Sanding

- Polishing

- Deburring

- Drawing/sandblasting/oxidizing black/

- Laser carving/silk printing

Quality documents

- Certificate of Conformity (CoC) that meets customer specifications

- First Article Inspection (FAI)

- Material certification and heat batch number

- ISO 2015

- ISO 9001