Product-performance testing

Performance testing is a process of testing the performance of magnesium alloys, aluminum alloys, stainless steel products, or raw materials, such as corrosion performance in the air, rigidity, adhesion, and metal weight. To achieve the most standard metal workpieces.

How does Greenbat Technology conduct performance testing?

Greenbat Technology has its own testing machines, such as salt spray testing, adhesion certification machines, and cold and thermal shock testing equipment, which can quickly inspect the performance of the produced metal workpieces. Finally give the customer a satisfactory answer

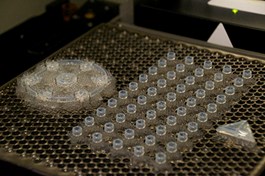

The newly-built parts are taken out of the machine and entered into the laboratory. In the laboratory, the salt spray tester, thermal shock instrument, etc. are used to create a simulated natural environment for the metal workpiece, and accelerate the rigidity in the natural environment. Corrosion, adhesion and other aspects of testing, performance testing is an important means to assess the ability of products or materials in various aspects, the scientific and reasonable test results are of vital importance. There are many factors that affect the stability and consistency of performance results. To improve the effectiveness of performance results, test technology is the key.

- Fastest delivery within 1 day

- Real-time quotation of magnesium alloy CNC parts

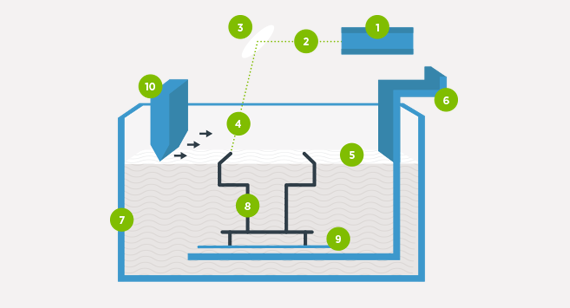

- Salt spray test

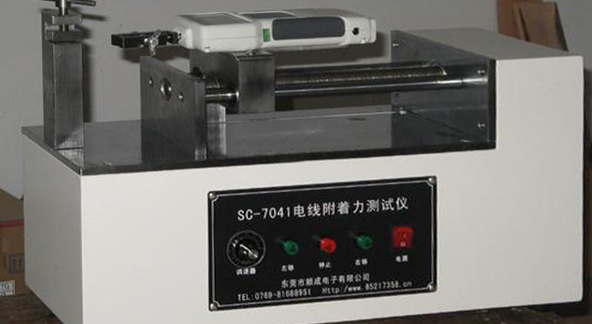

- Adhesion certification

- Thermal shock

Adhesion certification

When the circular forging die is pulled away from the coating surface, the indicator on the scale shows the value of adhesion, which is expressed in terms of the force required to pull away from the forging die.

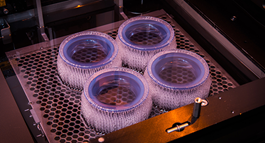

Salt spray test

The salt spray test of metal workpieces is generally divided into two categories: one is the natural environment exposure test, and the other is the artificial accelerated simulated salt spray environment test.

CNC Machining Magnesium Alloy Design Guidelines

Data resources

Industrial 3D printing for dummy

What is additive manufacturing

Introduction to Stereo Lithography (SLA) 3D Printing

Choose materials for stereo lithography (SLA) 3D printing