Surface-power treatment

Electric power processing is a process of industrial use of electrolysis to cause a chemical reaction between the metal surface and the solvent, which can produce functional magnesium alloy prototypes and end-use production parts within one day. Compared with the chemical surface treatment process, the final part has a high-quality surface finish, excellent feature resolution and more consistent mechanical properties.

How to perform surface electrical treatment?/h2>

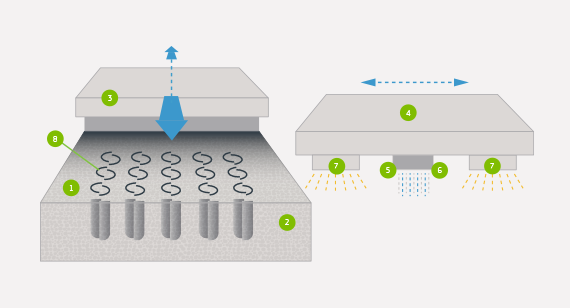

Electric surface treatment uses chemical agents, which are melted into a solid layer through electric components through electrolysis. After each layer, the chemical solvent is distributed to the product surface, and then the process is repeated until the product surface treatment is completed.

Greenbat Technology has complete surface treatment capabilities, including magnesium alloy micro-arc oxidation, anodic oxidation, electroplating, electrophoresis, and gold conductivity. The power-treated products have high surface resolution, surface coating, high precision, and high degree of protection. The metal is not oxidized, and can well protect the appearance from scratches and damage.

- Fastest delivery within 1 day

- IS9100 certification

- Micro arc oxidation

- Anodizing

- Electroplating, electrophoresis, gold conductive

Talking about the Surface Treatment Methods of Magnesium Alloy Electroplating

For some magnesium alloy products, in order to prevent oxidation, we can galvanize, which is also a cheaper method in electroplating.

What is the classification of magnesium alloy electroplating process?

Electroplating is a process in which a thin layer of other metals or alloys is plated on the surface of certain metals using the principle of electrolysis. According to the composition of the coating, the electroplating process can be divided into five categories: chromium electroplating, copper electroplating, cadmium electroplating, tin electroplating and zinc electroplating.

Design criteria

Data resources

Current Status of Magnesium Aluminum Alloy Surface Treatment Technology

Corrosion resistance of magnesium and magnesium alloys in the atmosphere

Influence of impurities on the corrosion resistance of magnesium alloys

Selection of Copper Plating Process for "Copper Clad Steel" Magnesium Alloy