Post-treatment of product surface

Choose from metal surface treatment options to enhance parts, improve appearance and other benefits.

Clear coating can be used It is usually applied to the part to produce a transparent surface treatment effect. You can also paint on metal parts. You need to do some sanding and polishing to make the surface smooth, then you can cover and paint the parts with any color you want, just send the product number together with the design upload, And attach the CAD model to indicate which color. The parts are sprayed with military-grade paint. You can also use touch painting.

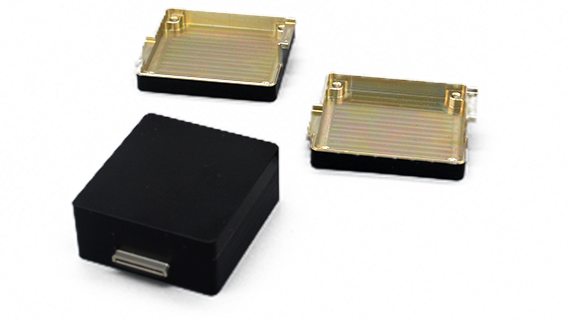

Plating on metal parts can improve the strength and durability of magnesium alloy parts. Electroless nickel plating is a good way to imitate cast aluminum or magnesium parts to reduce weight.

Chemical surface treatment, electric surface treatment, and mechanical surface treatment may be on metal parts, and the parts can be dyed black, green, red, blue or yellow. Simply soak the finished part in a chemical solvent for a while to get a consistent color. This option is one of the fastest and lowest cost ways to make printed parts attractive. There is no chance to cover up certain areas like painting, but for parts made of magnesium alloy, aluminum alloy, and stainless steel, especially parts made of magnesium alloy materials, this is usually a good choice.

Decals

are a great way to attach company logos, safety warnings, and other graphics to increase appearance or functionality. We do not provide these products, but can apply them for you. Please note that adhesives and thermal transfer decals will not stick to the rough surface characteristic of some metal parts, making sanding or smoothing the target surface a prerequisite for the application of decals.

Texturing

It can make metal parts less slippery, thereby improving the finish of metal parts, improving ergonomics, and improving appearance. When prototyping metal parts and then die-casting them, spray textures can be applied to imitate the appearance of your company's brand used in many cavities. You can use this same technique to apply a soft paint or polyurethane clear coat on metal parts,

This process can also improve the weather resistance and solar resistance of the UV curable materials used in SLA.

Polishing can be performed on metal parts to create high-quality surface effects. Likewise, a certain degree of smoothing is required to apply paint and decals, but a highly decorative surface can be further adopted. If this is required, you will need to use graphics or screenshots to determine your final expectations for the part.

Electrolytic treatment The process of direct electrical power treatment on metal parts, thereby eliminating heat-induced stress and potential warpage. It is also used to harden magnesium alloy metals, strengthen them, make them less prone to cracking and fatigue, or make them more flexible. If you are looking for a very hard and hardened metal, magnesium alloy is a good choice.

Secondary machining is a process that can be performed on magnesium alloy parts if a high-precision, smooth surface is specified. Other demanding operations for magnesium alloys include boring or reaming tight tolerance holes or tapping those holes that require threads. Depending on the material, various types of blades can be electrolyzed or glued in place.