Surface-mechanical treatment

Mechanical surface treatment is a process that uses machinery to polish and polish the surface of a product. It can create functional end-use parts with mechanical isotropic properties and smooth surface finish. You can choose from rigid and flexible magnesium alloys, aluminum alloys, and stainless steel materials to meet your application requirements for high-impact components.

How does mechanical surface treatment work?

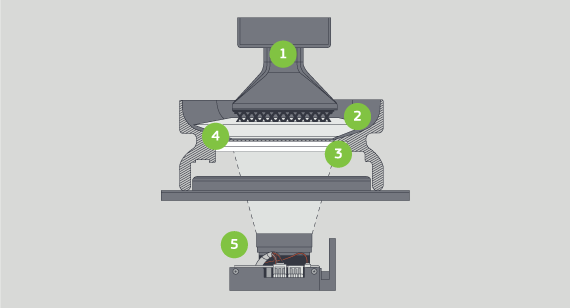

The mechanical surface treatment uses grinding machines, polishing machines, wire drawing machines and other mechanical (continuous liquid interface production) technical processing to produce parts. Its working principle is to smooth the surface of the product and form the shape and pattern required by the product. With the emergence of a series of mechanical surface treatments, the parts solidify and the build platform rises.

The core of the mechanical treatment process is grinding, polishing, and wire drawing. The surface of the product has undergone three mechanical treatments, forming a smooth surface and a brushed metal interface, making the product more precise and beautiful. The laser engraving and silk screen printing are also part of the mechanical processing of our Green Bat Technology. It is mainly through the laser engraving machine and the silk screen printing machine to print text or patterns on the product surface to form a one-stop processing service for the product.

- Fastest delivery 3 days

- Complex designs that are difficult to form

- Need isotropic mechanical properties and smooth surface finish

- Grinding, polishing, wire drawing, tapping

- Laser carving, silk screen,

Polished, polished, brushed

Grinding, polishing, and wire drawing is a process of using machines to make the surface of the product form different surfaces, smooth, or metal lines

Some simple methods for surface treatment of hardware accessories

Nowadays, most products in this society are processed through hardware accessories, but the surface processing steps of hardware accessories may not be understood by everyone.

Design criteria

Data resources

Processing of large magnesium alloy structural parts

Hardening process of cast magnesium alloy parts

Full-service CNC machining services

Computer reinforcement processing fastener manufacturer