Magnesium alloy die casting processing service

Formed prototypes and small batch production parts can be completed within one day at the fastest

Certificate of Certification

ISO 9001:2015 | Military Quality Certification

Are you ready to manufacture parts in a more cost- and time-saving way? Our reasonably priced molds (starting at RMB 7,500) and fast turnaround time (as fast as 1 day) can help you reduce design risks and limit overall production costs at every step of the entire product cycle.

Are you ready to manufacture parts in a more cost- and time-saving way? Our reasonably priced molds (starting at RMB 7,500) and fast turnaround time (as fast as 1 day) can help you reduce design risks and limit overall production costs at every step of the entire product cycle.

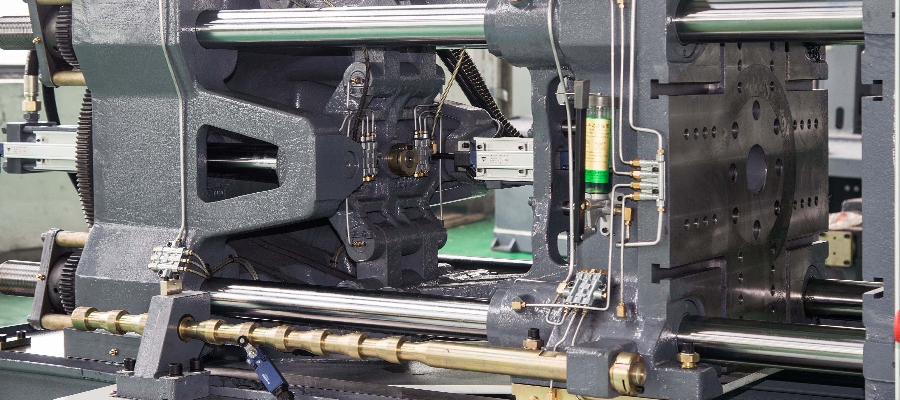

Die casting process

Die casting molding

Die-casting molding is a manufacturing process in which the magnesium alloy liquid in the barrel is heated to a molten state, and then injected into the mold to form the final production grade magnesium alloy part.

Injection molding

Pouring molding is a casting process in which a compound of two components is mixed together and then thermally cured with a catalyst in a mold to produce the final part.

Precision die-casting machining

Die-casting molding and casting molding are two-part casting molding processes, in which one material covers the second base material part or metal insert to form a single component.

Made on demand

That is what we often call pressure processing and casting processing. The pressure processing method is widely used. Relatively speaking, there are more processing modes.

You can choose small batch processing methods, and With a large number of processing methods, we can provide you with rapid prototyping and processing products.

Why choose the die-casting process of Qingbat Technology?

"The Green Bat Technology has brought us a lot of inspiration. We can extract parts from actual materials at a very fast speed for use in final production."

Additional links and resources

Record number: Guangdong ICP No. 14004399 @cyanbat